CCAA EH&S Award Winners Announced at WA Construction Materials Industry Dinner

The 9th CCAA WA EH&S Awards were held at the Construction Materials Industry Dinner on Friday 14 August 2015 at the Crown Burswood Astral Room, Perth.

In 2015, 28 entries were submitted across the seven awards, which focus on improving environmental performance and health and safety outcomes.

This year a new category was introduced in WA, Community Engagement, to acknowledge excellence in communication with the community on all activities, including Environment & Safety.

Health & Safety Best Performance - Concrete

WINNER- Hanson Canningvale - Concrete Plant Upgrade

From the start the concrete plant upgrade was designed to be forward thinking and eliminate as many hazards as possible. The incline conveyor running material to the overhead bins was installed with walkways either side of the belt. This allows workers and contractors to inspect, maintain and repair any part of the conveyor without requiring an elevator work platform reducing working at heights risk. Additionally the installation of the modular designed ground bin applies industry best practice.

Health & Safety Best Performance - Extractive

Health & Safety Best Performance - Extractive

WINNER - Boral Orange Grove Quarry - Whole Site Safety Initiatives

This quarry put up 4 quality entries which were the Community Reference Group, Dust Monitoring and data system, Command Apex with Dual Weighbridge and Skycan Lightning detection.

Health & Safety Innovation

WINNER - Hanson Canningvale Concrete - Removable Ground Bin

Health & Safety Innovation

WINNER - Hanson Canningvale Concrete - Removable Ground Bin

The ground bins are in two parts: grizzly on top, bin on the bottom. The grizzly can be lifted out, then the bin and grizzly replaced. The bin can be upturned and repaired at ground level, negating the need for confined space or the risk of engulfment. This also means that the grizzly goes back in and the plant can operate with total downtime of less than half an hour whilst repairs are undertaken. This Engineering solution was achieved by rebating vertical sections in the tunnel which are slots that keep the trafficable parts in and at a cost of $50,000 was well worth it for the reduction in risk, as well as added benefits in significantly reducing downtime for roller changes and ground bin repairs.

Environmental Best Performance - Concrete

Environmental Best Performance - Concrete

WINNER - Holcim East Perth - Whole Site Initiatives

For Whole Site best practice in all areas regarding material handling, waste, water, dust and noise management which are contained in a detailed environmental management plan. Three Additional improvements this year include Community Engagement which sees an average of 100 students per visit from Curtain University shown on a 90 minute tour of all the environmental and safety controls at the plant. They also installed 2 safety items which were the pedestrian Warning System at the Front gate and a Steel Fibre Machine to reduce manual handling.

Environmental Best Performance - Extractive

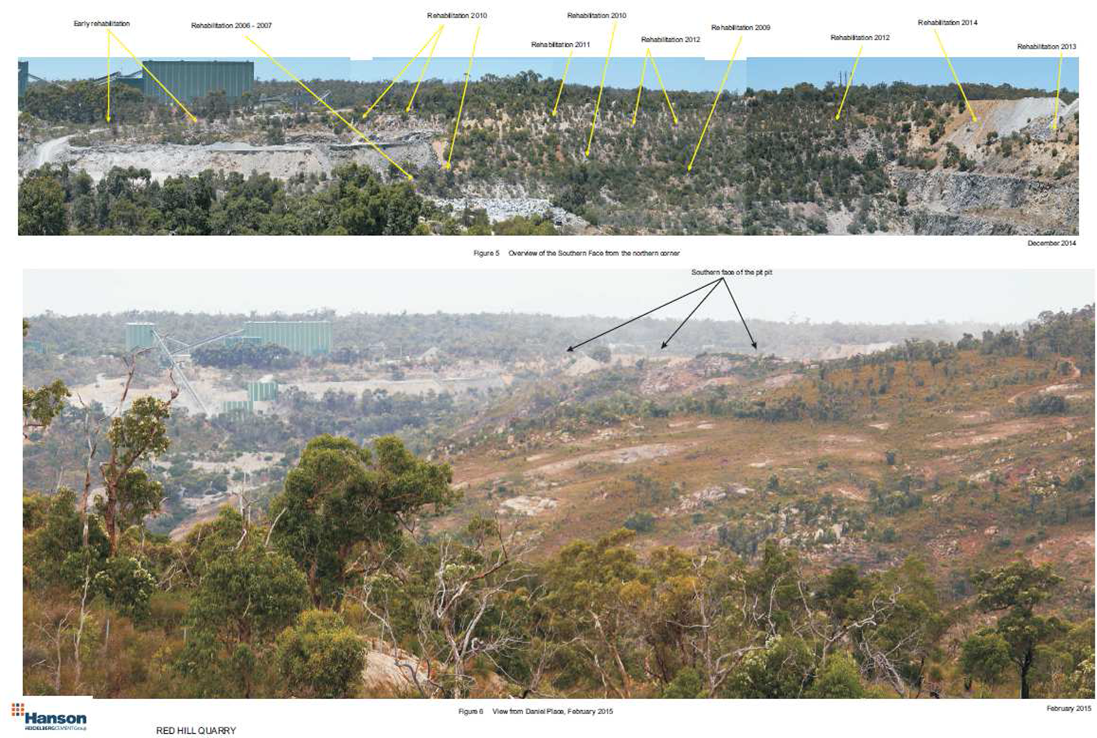

WINNER - Hanson Red Hill Quarry - Screening Rehabilitation & Revegetation

For ongoing Screening, Rehabilitation and vegetation management of the site according to a documented plan which includes a summary of the geology, soils, hydrology and flora with particular reference to land stabilisation and rehabilitation of disturbed areas, along with visual impact management strategies. A progress report is compiled annually and independently audited every two years, this report is also circulated to local residents, local groups and Government Departments. Public consultation days are conducted annually with local residents invited to tour the quarry and given the opportunity to discuss issues and future development of the site.

Environmental Innovation

WINNER - Boral Orange Grove Quarry - Foam Dust Suppression System

Environmental Innovation

WINNER - Boral Orange Grove Quarry - Foam Dust Suppression System

By using a technique to add foam which has a texture like shaving cream into the crushing circuit they were able to adequately suppress dust while still retaining full screening capacity. Water addition was the only control measure previously available for dust suppression in the crushing circuit but this did not allow the screens to operate effectively. The use of foam as a dust suppression technique has added just a few cents per tonne to the crushing costs, but has reduced the clean-up, and the fugitive dust levels, which has provided significant benefits to both the quarry and the surrounding community. Since its installation in December 2014 there hasn’t been a single dust complaint received from the local or wider community and the monthly dust deposition results are significantly lower than previous years showing a distinct improvement.

Community Engagement

Community Engagement

WINNER - Holcim Bunbury Quarry - Telstra Messaging Integrated Service

For their Short Message integrated Service which notifies the local community of quarry blast days and times through a text messaging system set up through the quarry’s blast notification distribution list. This allows a direct line of communication for the community to the quarry by one of two methods:

•Either responding to the text which is sent directly to the Quarry Manager in the form of an email, or

•The recipient can phone the number provided in the message putting them in contact with the quarry office.

This enables the community to engage with the quarry if they have any questions relating to the scheduled blast or quarry operations, reducing the likelihood of the community feeling aggrieved by the quarry blast operation and enables the quarry to facilitate active consultation by getting feedback on how different blasts can affect different areas of the community. The process has been in operation for 3 years and works well with little inconvenience or imposition to site or community, while also providing an active presence.

The winners of the Environmental Innovation and Health & Safety Innovation Awards will now be entered into the national awards, which along with the winners in 2016, will then be awarded at the CCAA IQA Construction Materials Industry Conference.

“The entries this year were of a high calibre. Hopefully, they will motivate the broader industry to investigate whether they too can make simple, cost effective changes within their businesses in order to improve environmental, health & safety and community engagement outcomes”, Harry Backes, WA State Director said.

For further information contact Harry Backes on (08) 9389 4452 or email

[email protected]