CCAA EH&S Award Winners Announced at QLD Construction Materials Industry Dinner

The CCAA EH&S Awards in Queensland were conferred on Friday 21 August by the Minister for State Development, and Minister for Natural Resources and Mines, the Hon. Dr Anthony Lynham MP at the Construction Materials Industry Dinner at the Sofitel Brisbane.

In 2015, a record 30 entries were submitted across the three awards, which focus on improving environmental performance, health and safety outcomes, and community leadership. Since the commencement of the awards in Queensland in 2011, there have been almost 130 innovations put forward by member companies to share good practices.

ENVIRONMENTAL INNOVATION AWARD - WINNER

WAGNERS CEMENT - VERTICAL ROLLER MILL INSTALLATION

The cement manufacturing process is very energy consumptive. Over the last 40 years, the cement industry has strived to improve its energy and fuel efficiency in an attempt to reduce the environmental impact. However, in order to substantially reduce CO2 emissions, the volume of clinker in cement also needs to be reduced.

Over the last two years, Wagners have commercialised a geopolymer concrete (EFC) which is produced solely from flyash and slag with no clinker addition. The key to the success of the EFC has been the high fineness of the ground slag, which has been achieved through the installation of a Vertical Roller Mill (VRM) at Wagners Pinkenba Cement plant.

The VRM has resulted in a 35% reduction in electrical energy consumption when producing General Purpose Cement. The VRM has also provided for additional capacity and increased production rate. The system also provides for additional capacity, further electricity savings by operating in off-peak periods, and improved product quality as the VRM is more responsible to control inputs than a traditional ball mill.

ENVIRONMENTAL INNOVATION AWARD – HIGHLY COMMENDED

HOLCIM AUSTRALIA

MOOLOOLAH SAND PLANT - STORMWATER HANDLING SYSTEM

The Holcim Mooloolah Sand Plant sits in a floodway and below the Ewan Maddock Dam. In order to manage significant storm water events, the Mooloolah Sand Plant team have embarked on an innovative solution which includes construction of a flood gate, drainage channel improvement, hydro-seeding, and stormwater management protocol.

The team has also worked closely with the Department of Environment and Heritage Protection in the design and establishment of the flood gate which ensures that the local river system is protected. During flood events it is not practical or possible to safety access the site to take water monitoring tests, so a system of rising stage samplers has been implemented that take up to 26 real time samples during a flood event.

COMMUNITY LEADERSHIP AWARD - WINNER

BORAL CONSTRUCTION MATERIALS AND CEMENT

ORMEAU QUARRY – COMMUNITY RELATIONSHIP INITIATIVES

Since 1994, Boral has been partnering with Landcare to improve the local catchment area flowing through the buffer land at their Ormeau quarry, commencing with the Pimpama River Revegetation Partnership. In 2005, Boral implemented their “community liaison group model” which provides a forum for discussing and sharing information with the local community.

Two long term goals were identified where Boral could assist with the local Ormeau community including creating a continuous riparian zone along the upper reaches of the Pimpama River, and to support Landcare by establishing a permanent base in the area. In recognition of the 20 year partnership, Boral has provided a dwelling in close proximity to the quarry- Darlington Conservation House - which provides a permanent base for Landcare, as well as providing a meeting point for many other community groups to facilitate environmental programs.

The ongoing partnership has also achieved a continuous riparian zone, spanning over 6 kilometres, as well as the creation of the Boral Environmental Reserve, an area of some 3 hectares set aside on Boral’s land for the local community to enjoy, demonstrates how industry and community can work together creating significant positive outcomes for the environment.

HEALTH AND SAFETY INNOVATION – WINNER

HOLCIM AUSTRALIA

MOUNT CORDELIA QUARRY – QUARRY SCREEN CHANGE SAFETY SLED

A regular activity that is conducted across quarries is the maintenance and changing out of screening decks. The work can be awkward and often requires having a person positioned with the screen deck infrastructure to make adjustments or undo/tighten components.

Through review and consultation, the Holcim Australia team at Mount Cordelia Quarry has come up with an innovative solution by devising a sled which can be safety lowered into the screen by a second person using a winch. Since its inception, the screen change sled has become a welcome addition to managing screen change activities on site.

The sled has also reduced the likelihood of strains, sprains and injuries, assists personnel with working at heights safely, and reduces screen change out times. The sled can also provide an insulation barrier when using electrical equipment, as well as a first aid recovery stretcher.

HEALTH AND SAFETY INNOVATION – HIGHLY COMMENDED

HEALTH AND SAFETY INNOVATION – HIGHLY COMMENDED

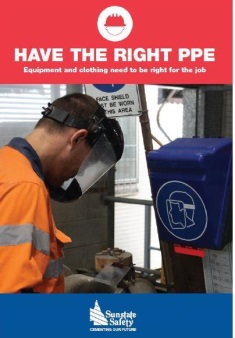

SUNSTATE CEMENT

SAFETY CULTURE INITIATIVES

In their quest to create a strong safety culture, Sunstate Cement have implemented a range of initiatives including a

safety video, safety posters, and splash screen. The video uses their own employees, together with real life stories taken from the workplace. The actual shooting of the video generated a tremendous engagement from the team, with 40% of the workforce having “starring” roles.

The video was released in parallel with a poster campaign which were developed and produced by Sunstate Cement using employee images. Each month a safety poster with a new theme is displayed across the site to reinforce the message and provide continuity. The video and poster campaigns have been complemented by a computer ‘Splash Screen’ displaying safety messages and statistics. The safety initiatives have shown significant improvements including a 30.4% increase in Job Safety Analysis procedures (JSAs), 16.9% increase in hot work permits issues, and 74.3% increase in confined space entry permits issues.

CCAA would also like to thank our award sponsors - HWL Ebsworth, Sunstate Cement and Hopgood Ganim, participating sponsors - Holcim Australia, Liebherr Australia, Mapei Australia,Riverside Industrial Sands, and Wagners, and Queensland Government Supporters Workplace Health and Safety Queensland and Department of Infrastructure, Local Government and Planning